I still remembered I was shocked when I saw the water transfer printing sculpture for the first time, what an amazing product it was! Each sculpture with a unique pattern, but the whole texture is very natural and fits the modern style well. Our factory needs a niche style like water transfer printing! In this article, we will share with you the knowledge related to resin sculpture water transfer printing from a Chinese supplier’s perspective.

What is Water Transfer Printing?

Water transfer printing is a printing process that transfers patterns from a water-soluble film onto the surface of three-dimensional objects using water pressure. This process involves placing the water-soluble film that contains the printed patterns on the water’s surface, allowing the activated film to transfer onto the sculpture’s surface under water pressure. The final step is to apply varnish after the sculpture has dried. Water Transfer Printing not only achieves various effects but can also be applied to the decoration of various products without damaging their appearance and performance, making it widely used in product decoration.

1. What are the advantages of water transfer printing?

- Easy production: achieve 3D printing easily.

- Multiple patterns are available: water transfer printing can use a variety of patterns, making the printed products diverse.

- Cost-saving: compared with traditional printing processes, water transfer printing is simpler, saves time and effort, and can save production costs.

- Good durability: the printed pattern can have good durability and waterproof performance after processing.

- Versatile: can be applied to various products with different shapes, achieving a full-range and no-dead-angle printing effect.

2. What are the disadvantages of water transfer printing?

- High environmental requirements: it requires specific temperature and humidity conditions, otherwise it will affect the final result.

- Professional skills required: professional skills are needed, as the improper operation will affect the printing quality.

- One-time printing: it is typically a one-time process and cannot be repeated. Therefore, once a problem occurs, it needs to be reprinted.

- Some limitations: it is only suitable for objects with flat or simple geometric shapes and cannot be adapted to complex shapes and curved surfaces.

Water Transfer Printing Resin Sculptures

Water transfer printing is widely used in producing small to medium-sized resin sculptures, offering a variety of patterns and effects such as wood grain, stone grain, and marble texture. A simple production process with low cost and high efficiency is the main reason why water transfer printing is a popular choice for many manufacturers.

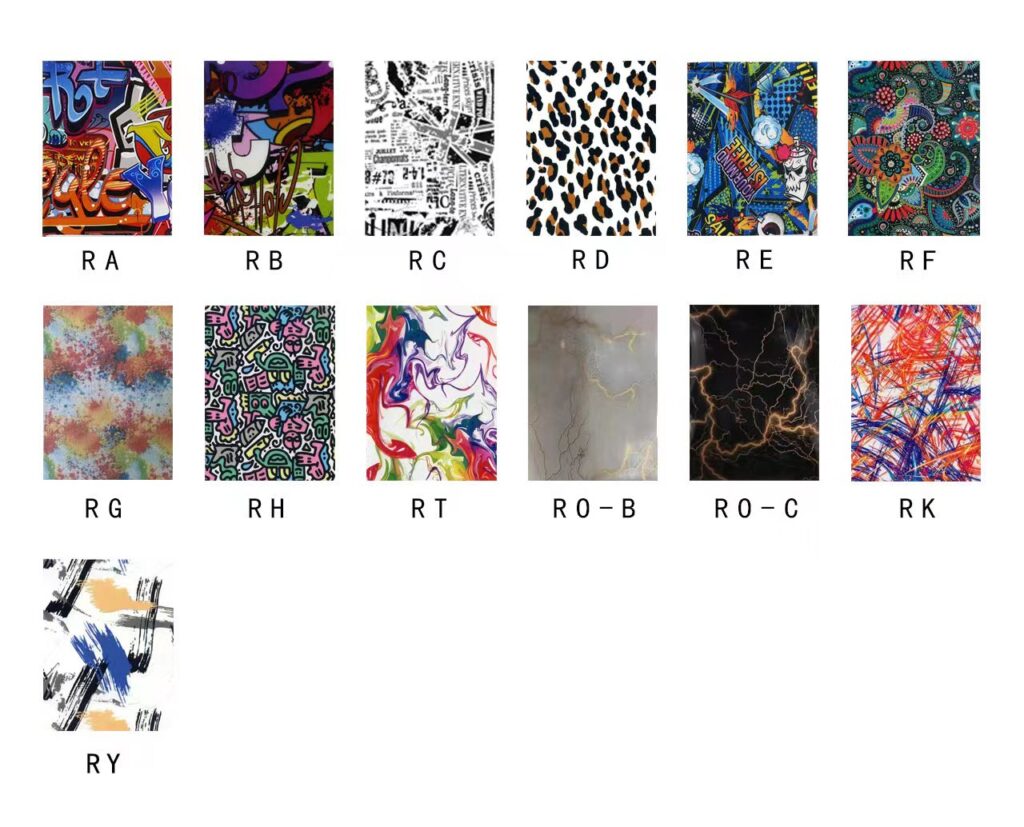

Our factory specializes in producing indoor resin sculptures. We utilize water transfer printing to incorporate diverse patterns, such as marble texture or graffiti style, to enhance the artistic and decorative appeal of the sculptures. We offer up to 13 pattern options, below picture for your reference, please kindly help to check.

1. What is the production process for water transfer printing resin sculpture?

- Place the water-soluble film that contains the printed patterns on the surface of the water.

- Spray activator to dissolve the film and turn it into a fluid state.

- Press the resin sculpture from top to bottom into the water, allowing the activated film to transfer onto the surface of the sculpture via water pressure.

- After removing the resin sculpture from the water, wash away any excess water transfer film and activator residue.

- The final step is to apply varnish after the sculpture has dried. It’s important to wait until the resin sculpture is completely dry before applying the clear coat.

2. What are the production difficulties for water transfer printing resin sculpture?

- Transfer film with high elasticity: the activated film will deform easily due to its high elasticity, this is the reason marketplace patterns use wood grain, marble, and animal patterns as the deformed film will not affect the final result a lot.

- Using the appropriate transfer film: the right transfer film with reasonable adaptability and quality will affect the final transferred sculpture result.

- Activate film process: during the printing process, it’s crucial to ensure the accuracy and stability of the colors and patterns. The handling of details also requires skill and experience.

- Soaking process: precise control of the soaking time and temperature is crucial for achieving optimal results. Both excessively short and excessively long soaking times can have negative effects, while the incorrect temperature can also result in issues.

- Transfer process: control the right pressure and speed to ensure the pattern is transferred with integrity and clarity. The complexity of the sculpture shape will affect the transferred result.

- After-treatment process: after completing the transfer process, it is necessary to carry out after-treatment steps, including cleaning, drying, and polishing. Each step requires a careful and patient operation to achieve the final desired result.

3. Our factory water transfer printing patterns

Our resin sculptures with a marble pattern have a realistic marble texture that is lighter and more convenient for transportation than real marble sculptures.

Graffiti-style patterns applied on sculptures using the water transfer painting technique create a stylish and personalized atmosphere, leaving a striking and memorable impression on the audience. These patterns consist of various colors and shapes, conveying a unique and contemporary art style.

Summary

Water transfer printing is a method of applying various patterns onto resin sculptures. This technique allows for different textures, colors, and patterns to be applied to resin sculptures at a relatively low cost and with higher production efficiency.